high-quality, reusable material, reducing waste and supporting circular economies.

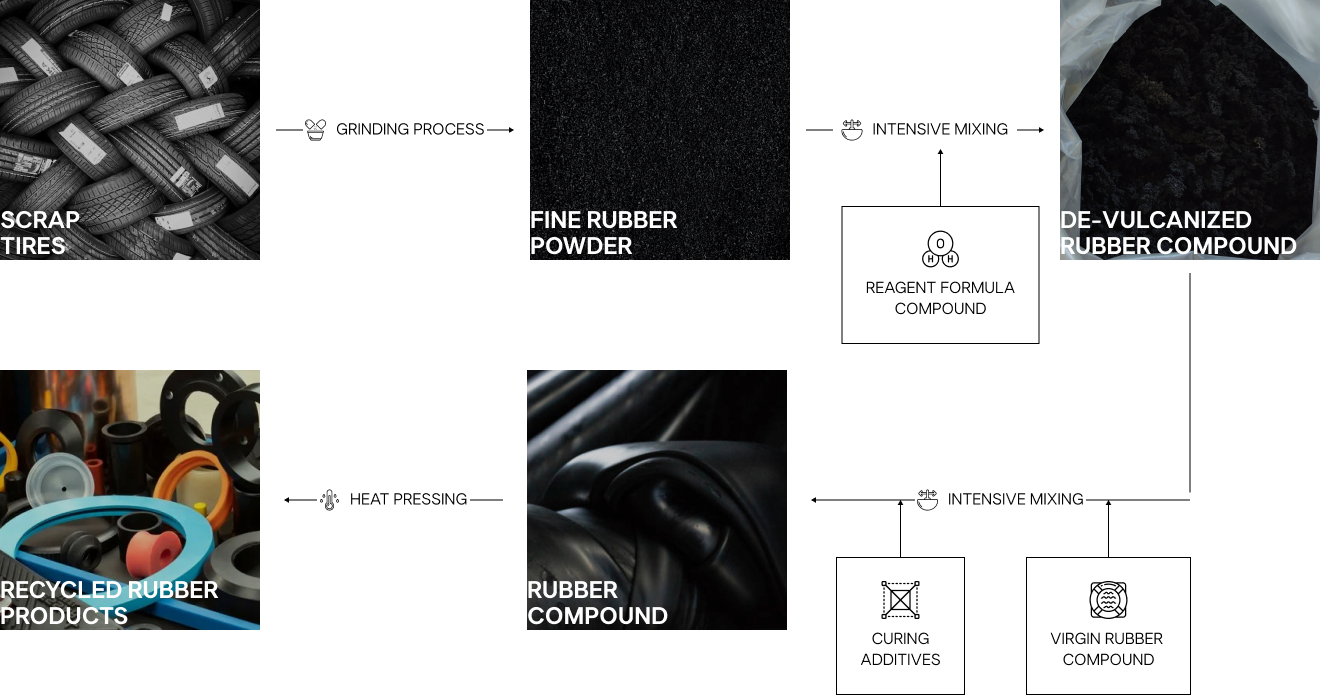

Traditional rubber recycling methods often fail to retain the material’s performance characteristics, leading to inferior products. Emcomat’s unique reagent compound enables rubber to be devulcanized and reused without compromising its strength, elasticity, and durability.

Emcomat’s breakthrough lies in its ability to devulcanize rubber while preserving its original properties such as strength, elasticity, and durability. Our customizable reagent adapts to various rubber types, ensuring unmatched efficiency and versatility across diverse industrial applications.

Unlike conventional methods, our compound preserves the rubber’s original properties, making it suitable for high-performance uses.

The reagent can be tailored for different rubber types, ensuring optimal results for diverse industrial applications.

Every year, over 20 million tonnes of rubber waste is generated globally, with the majority ending up in landfills or incinerators. This not only contributes to growing waste piles but also poses serious environmental risks due to the toxic chemicals in untreated rubber.

Our process doesn’t just recycle rubber — it reduces the environmental burden in several ways

Recycling rubber uses less energy compared to manufacturing new rubber from raw materials, significantly reducing greenhouse gas emissions.

Our solution supports a closed-loop system, where rubber waste is continuously reused, reducing the need for virgin resources.

Recycled rubber means fewer tyres and rubber products in landfills, where they can take up to 500 years to decompose.

Converts rubber waste into usable materials without compromising quality.

Helps businesses reduce their carbon footprint and adhere to eco-friendly regulations.

By reusing rubber instead of producing new materials, companies save on raw material costs.

Long-term supply of the proprietary reagent will be contracted exclusively to Devulc at an agreed-upon price, ensuring consistency and quality.

Training sessions can be arranged to enhance your team’s skills and ensure smooth integration of the process.

Complete transfer of the chemical reagent development process, formula, and devulcanization method will be facilitated in a trustee office against a fixed fee.

Complete ownership of our devulcanization technology, including processes and formulations, for sustainable business growth.

Access expert-level guidance and support whenever required, provided under a flexible service fee structure.

The devulcanization process will be demonstrated in a lab for buyer evaluation, followed by formal testing of the end-product for quality assurance.

Complete transfer of the chemical reagent development process, formula, and devulcanization method will be facilitated in a trustee office against a fixed fee.

Empower your team with tailored training programs to operate the process independently.

Access expert-level guidance and support whenever required, provided under a flexible service fee structure.

Choose the investment plan that aligns with your vision for sustainable

growth and innovation.